Rigorous Quality Control for Every Investment Casting

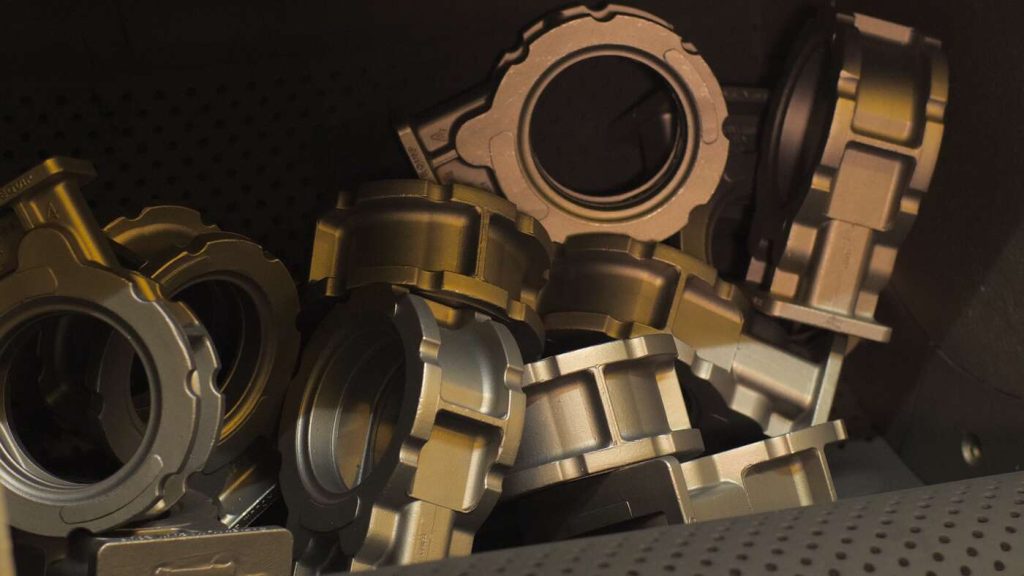

Investment casting quality control is our top priority at Eagle Precision Cast Parts. As a certified ISO 9001:2015 facility, we adhere to strict quality protocols and collaborate with customers to ensure that every casting meets performance, tolerance, and material requirements.

Whether you’re producing a small prototype or a complex assembly-ready part, we apply the same level of care and precision across the board.

Proven Quality Systems and Certifications

We are proud to hold multiple certifications that support our commitment to quality. Eagle Precision is an ISO-certified investment casting company that also complies with PED, RoHS, REACH, and other global standards. For documentation and downloadable certifications, visit our ISO/Certifications page.

Dimensional Integrity and Tolerance Standards

Dimensional accuracy starts early in the process. Our investment casting tolerances typically reach ±0.005″ per inch, with standard surface finishes down to 125 RMS. These tight tolerances are maintained through:

- 3D scanning and digital metrology

- CMM verification

- Custom gauging and in-process inspection

- Rigorous process monitoring and documentation

Explore our Investment Casting Tolerances Guide for more technical specifications and best practices.

Investment Casting Quality Control Tools and Processes

We use a combination of technology, expertise, and process discipline to ensure part quality:

- Keyence VL-550 3D scanner for reverse engineering and validation

- Brown & Sharpe CMM with PC-DMIS software

- Full ceramic lab and hardness testing capabilities

- LECO spectrometers for chemistry analysis

- X-ray inspection (Pantak HF320 system) for internal integrity analysis

- Climate-controlled shell room with continuous temperature/humidity tracking

These tools allow us to catch potential deviations before they reach customers, ensuring reliable part performance every time.

APQP and Early Design Validation

Our Advanced Product Quality Planning (APQP) process ensures every casting project begins with a detailed understanding of customer expectations. We start every program with a 25-point APQP checklist, asking questions such as:

- Will the part require heat treatment, machining, or painting?

- What are the critical dimensions or surfaces?

- What materials and environments will the part endure?

- Was this part previously cast elsewhere, and if so, were there issues?

This upfront planning minimizes risk and accelerates production timelines by reducing costly revisions downstream. Read this article to learn more about our APQP process.

Continuous Improvement Is Built Into the Process

Our engineers work closely with clients to refine designs before tooling begins, using MAGMAsoft simulation and SolidWorks modeling to spot issues early. This collaboration results in lighter parts, stronger geometry, and improved performance, often without increasing costs.

Quality is a continuous loop of improvement, spanning from internal audits to customer feedback and process refinements. We constantly seek new ways to strengthen our castings and service.

Ready to Start Your Project with Eagle Precision?

Partner with a foundry that makes quality a core discipline, not a checkbox. Contact us today to request a quote or speak with our technical team. We’re ready to deliver cast parts that exceed your expectations.