State-of-the-Art Investment Casting Facilities

Eagle Precision’s investment casting facility is purpose-built to deliver precision, flexibility, and repeatable quality. Located in Muskegon, Michigan, our 67,500-square-foot manufacturing and warehouse space is equipped to handle complex, high-tolerance parts in both prototyping and production volumes.

From wax injection to final inspection, every process is supported by advanced machinery, dedicated workspaces, and expert staff committed to getting your parts right, every time.

Our Investment Casting Facility

Our plant has been designed with efficiency and growth in mind. Multiple expansions have increased our capacity while maintaining tight environmental controls in critical process areas such as the ceramic drying room and shellroom.

Facility Address:

Eagle Precision Cast Parts, Inc.

5112 Evanston Avenue

Muskegon, MI 49442

Office Hours:

Monday–Thursday: 7:30 AM – 4:30 PM

Friday: 7:00 AM – 3:30 PM

Want a closer look? Explore our video and browse photos of Eagle Precision’s operations in action.

Complete Process Control from Wax to Final Inspection

Our investment casting facility houses everything required to produce high-quality cast parts from start to finish. Whether you need tight tolerances, unusual alloys, or complex geometries, our in-house equipment and skilled workforce are ready to deliver.

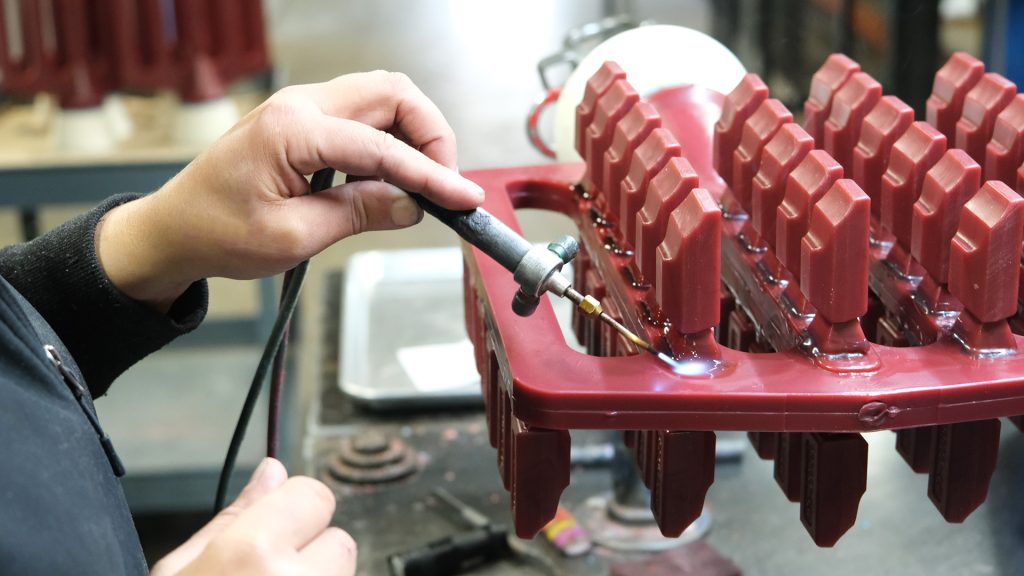

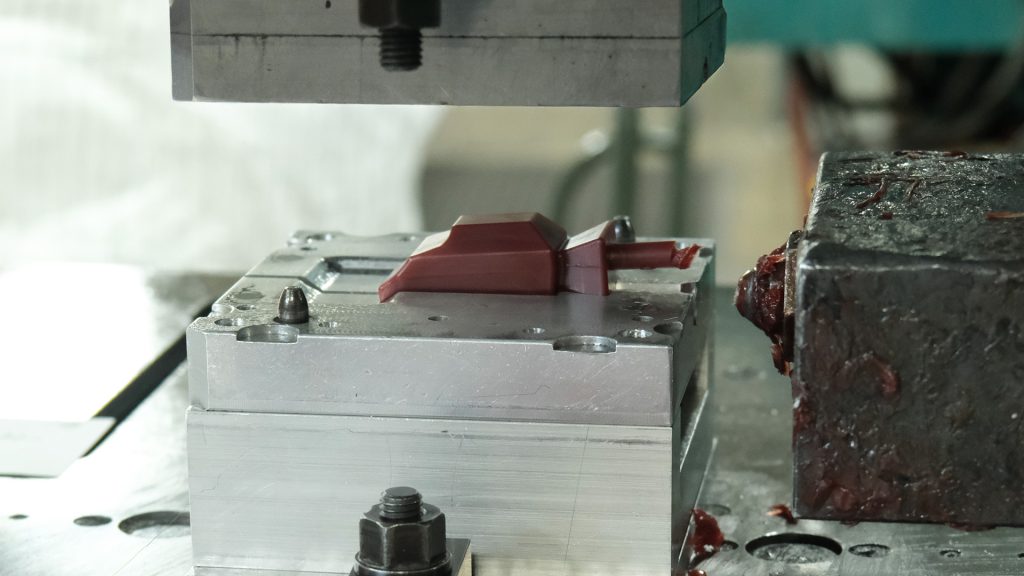

Wax Injection

- 1 50-ton wax injection press

- 6 25-ton wax injection presses

- 1 automatic wax press

- Dedicated chiller for wax temp control

Ceramic Shell Building

- Dip Mate robotic dipping cell

- 2 Romco fluidized beds

- 5 dip tank systems

- 2 rainfall sanders

- Pneumatic mold manipulators

- Climate-controlled ceramic drying room

- Fanuc robot with mold conveyor system

- 2 48″x60″ autoclave units

Melting & Pouring

- Multiple Pillar Mark VIII induction furnaces:

- 250 KW and 300 KW units

- 300–1000 lb. melt capacity

- 7 ceramic mold preheat ovens

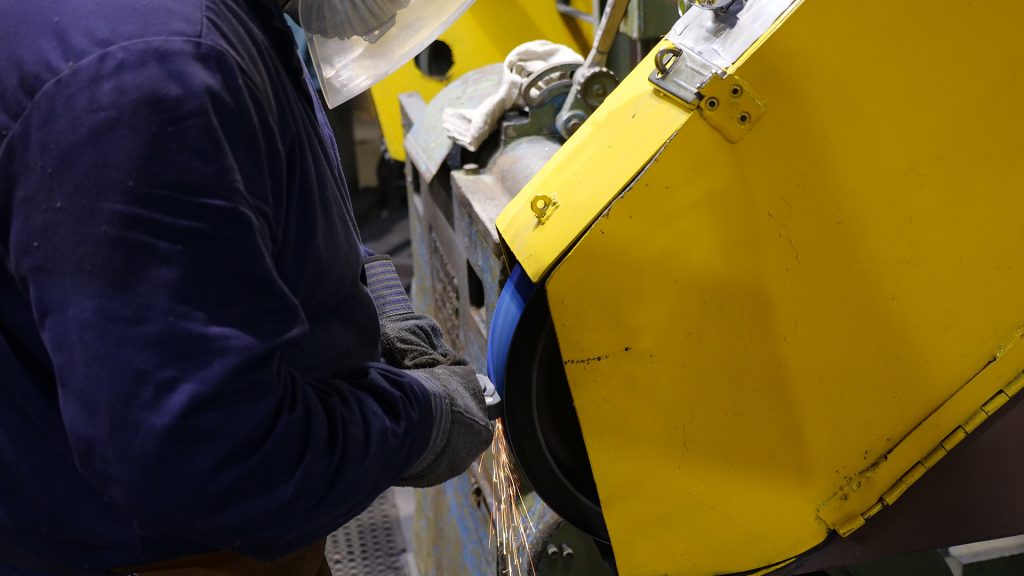

Cleaning & Finishing

- Pick and place robotic rotary table grinder

- Herschal knockout hammer

- Ramco ceramic leach tanks

- Pressure and sandblast cabinets

- Multiple Goff and Wheelabrator tumbleblasters

- Ener-Pac and Dake presses

- Assorted belt grinders and cut-off saws

Industry-Leading Quality & Metrology Capabilities

Consistent quality starts with solid process controls. At Eagle Precision, we use high-resolution inspection tools and temperature-controlled environments to validate both material and dimensional performance.

Quality Control & Testing Equipment Includes:

- Rockwell and Brinell hardness testers

- Full ceramic testing laboratory

- Temperature/humidity recorders in shell/dry rooms

- X-Ray System (Pantak HF320) for castings up to 2″ thick

- Dual Leco GDS-500A spectrometers (ferrous and non-ferrous alloys)

- Dimensional inspection:

- Brown & Sharpe CMM with PC-DMIS

- Creaform ExaScan 3D scanner with Geomagic Inspection

- Pin gauges, calipers, and custom-designed gauges

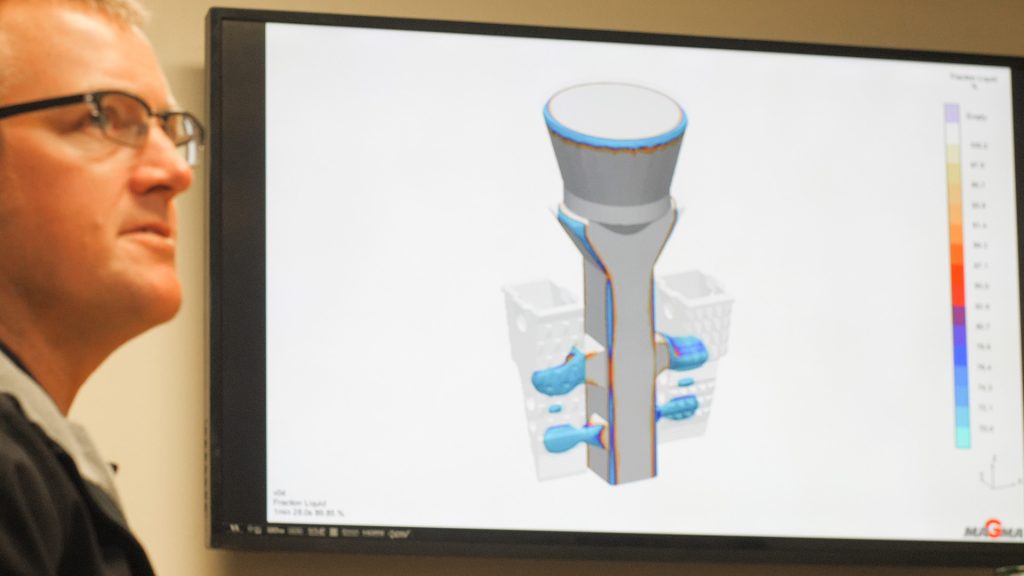

- Engineering Software:

- SolidWorks 3D modeling

- MAGMAsoft casting simulation

Designed for the Future of Investment Casting

What makes our investment casting facility stand out isn’t just the equipment—it’s how we use it. Robotics support shell building, digital simulation enhances gating design, and ceramic processing is monitored in real time. This integration ensures castings meet exacting standards while reducing rework, lead time, and cost.

By combining robust infrastructure with engineering depth, Eagle Precision delivers the consistency, responsiveness, and technical support expected from a top-tier investment casting partner.

Looking for a Facility Built to Handle Complex Projects?

Our team is ready to review your design and help you take full advantage of our advanced investment casting capabilities.