Our Legacy in Investment Casting Excellence

Eagle Precision Cast Parts was founded with a clear goal of providing our customers with high-integrity, precision-cast parts and exceptional service. Founded in 1991, Eagle Precision was established to complement the shell mold capabilities of its sister company, Eagle Alloy. Since then, we’ve grown from serving a single customer in military manufacturing to becoming a trusted partner for OEMs across various industries, including fluid handling, food processing, and transportation.

As a proud member of the Eagle Group, Eagle Precision brings decades of experience, deep technical knowledge, and employee-driven innovation to every project. From our 67,500 sq. ft. facility in Muskegon, Michigan, we deliver full-service investment casting solutions that help customers convert complex machined parts into streamlined, cost-effective castings.

A History of Continuous GROWTH

Mark Fazakerley and John Workman founded Eagle Precision to expand the group’s ability to serve customers requiring intricate geometries and tighter tolerances than traditional casting methods could offer. Our first order, a military antenna casting with weekly volumes of up to 2,500 pieces, was only the beginning. Over three decades later, we’re still producing that same part for that same customer.

Today, we manufacture more than 1,000 unique part numbers, including agriculture, oil and gas, mining, and government. As demand grew, so did our facility. Major expansions in 2012 and 2015 increased our floor space to 67,500 sq. ft., including over 17,000 sq. ft. of climate-controlled space. These upgrades support the full scope of our casting operations, from wax pattern creation to melting, cleaning, and final inspection, all in one location.

Our Values

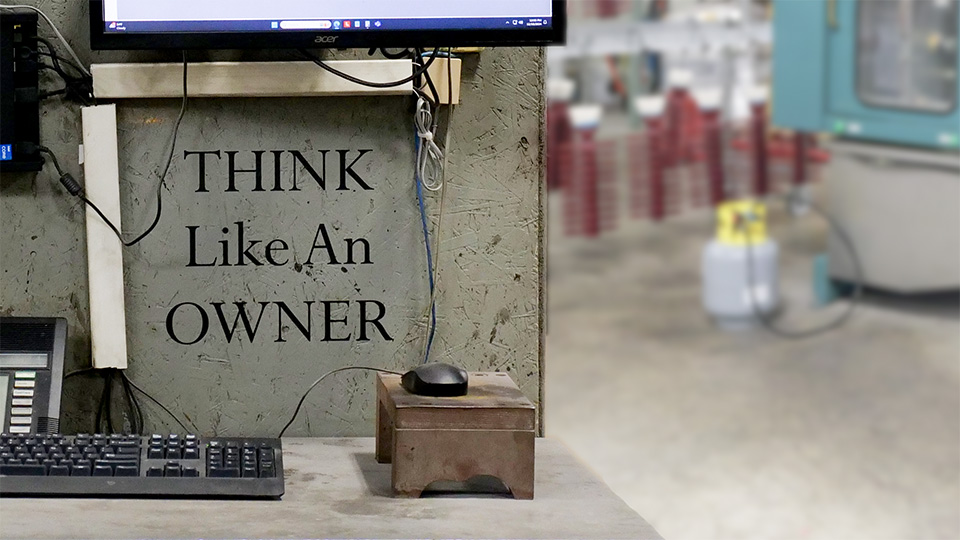

In order to achieve the long-term vision of the organization, Eagle Precision relies on associates at all levels who live and work by the following values.

The success of our customers matters, and we put their best interests first.

Value actions that are fair, responsible, and proper above all else. Conduct all activities according to the highest ethical standards and measures of social responsibility.

Recognize that everyone, and everyone’s work, is essential. Give the responsibility, authority, training, and tools necessary to make decisions to the person closest to the activity.

Take responsibility for our own assigned tasks and the performance of our workgroup. Focus on ownership versus blame when encountering setbacks. Demonstrate a can-do attitude by taking initiative.

Value working cooperatively with others at all times.

Foster an atmosphere that values quality, constant improvement, and creativity: encourage prudent decision making; and use mistakes as an opportunity for learning.

Establish effective, honest, and open communication among all employees, business units, and customers.

Be quick and flexible in responding to new opportunities and meeting customers’ needs. Embrace necessary change.

Our values are not just slogans. They show up in our safety practices, customer service, and problem-solving approach every day.

We always ask, “What is the right thing to do?”

Rooted in Our Community

Eagle Precision doesn’t just serve the manufacturing industry—we serve our community. Through charitable contributions and team volunteerism, we’ve supported organizations including:

- American Red Cross

- Child Abuse Council

- Community Foundation for Muskegon

- Love INC

- Mercy Health Partners

- Muskegon Rescue Mission

- United Way

- USS Silversides

- Wings of Mercy

Associations

Eagle Precision Cast Parts, Inc. is a member of the following associations:

- AFS – American Foundry Association

- SFSA – Steel Founders Society of America

- FAM – Foundry Association of Michigan

- VMA – Valve Manufacturers Association of America

- Muskegon Lakeshore Chamber of Commerce

A Strong US-Based Manufacturing Network

Eagle Precision is part of the Eagle Group(insert link), which also includes Eagle Alloy and Eagle CNC Technologies. Together, we offer a fully integrated supply chain, from casting to machining to final inspection.

The Eagle Group’s collaborative model allows us to take on more complex projects while maintaining flexibility, quality, and cost-efficiency.