Custom Investment Castings in Ferrous & Non-Ferrous Alloys

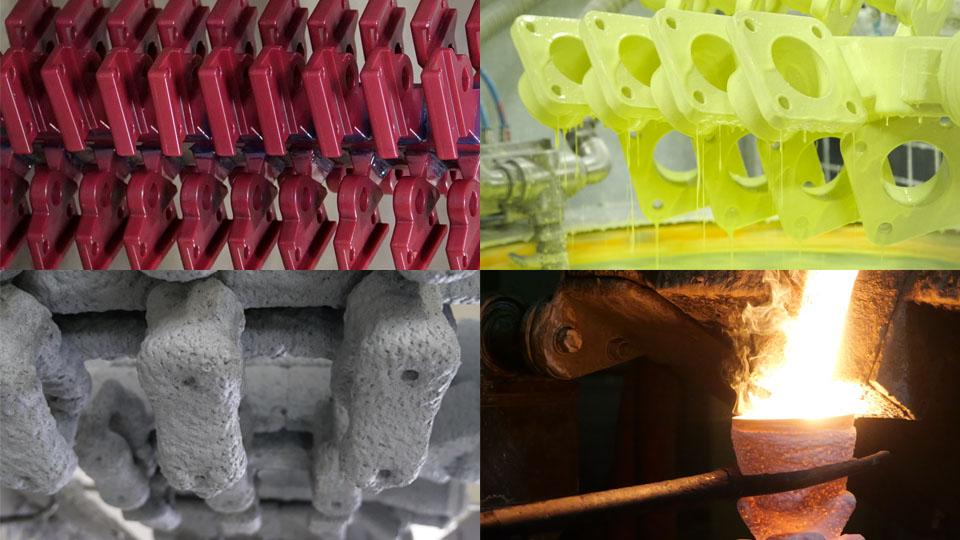

At Eagle Precision Cast Parts, we produce high-quality investment castings using the lost wax method. This process allows for tight tolerances, fine surface finishes, and excellent repeatability, even in complex geometries. We support a broad range of ferrous and non-ferrous alloys and offer full-service engineering from prototyping to production.

Our team specializes in helping OEMs and industrial clients design parts that strike a balance between performance, durability, and manufacturability. Whether you need stainless steel components for fluid handling or nickel-based castings for defense applications, Eagle Precision offers the technical depth and process control to meet your exact needs.

What Is Investment Casting?

Investment casting, also called lost wax casting, is one of the oldest and most precise metal-casting methods. It begins with a wax replica of the part. That replica is repeatedly dipped in ceramic slurry, dried to form a hard shell, and then the wax is melted out. Molten metal is poured into the ceramic mold. Once cooled, the shell is broken away, revealing a finished part that often needs little to no machining.

We use this method to produce components with:

- Tight dimensional tolerances (as tight as ±0.005″ per inch)

- Smooth surfaces (125 RMS standard)

- Minimal post-processing

- High consistency across production runs

Download our Investment Casting Guide for design standards, metal specifications, and guidelines.

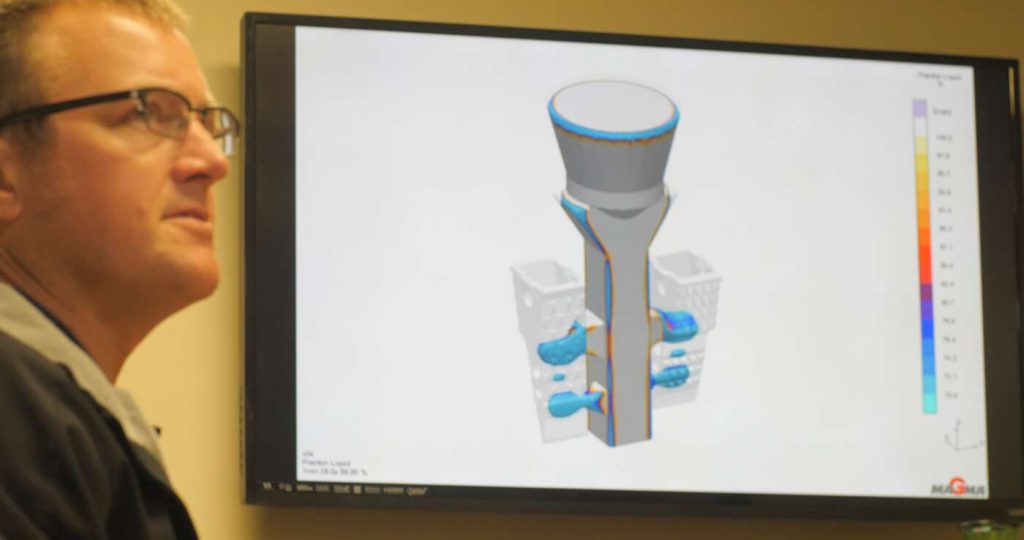

Modern Tools Meet a Time-Tested Process

Although investment casting has been used for thousands of years, today’s version is powered by advanced technology. At Eagle Precision, we incorporate:

- Solid modeling with SolidWorks®

- Simulation and optimization using MAGMASOFT®

- CMMs and 3D scanning for inspection and dimensional validation

Our thorough Quality Control process allows us to minimize tool changes, reduce waste, and ensure product consistency from the first part to the thousandth.

Materials We Cast

We support a wide range of materials, including:

- Stainless steels like 304, 304L, 316, and 316L

- Carbon steels like WCB

- Alloy steels like 8620 and 4140

- Bronze and brass

- Aluminum alloys

- Nickel-based superalloys

For more details, refer to our downloadable Investment Casting Quick Reference Guide, which includes dimensional tolerances, material options, and design tips.

Investment Casting Compared to Other Metal Casting Methods

| CASTING METHOD | TOOLING COSTS | LABOR COSTS | TYPICAL TOLERANCES | SURFACE FINISH | TYPICAL VOLUME |

|---|---|---|---|---|---|

| Investment Casting | Medium | High | ±0.005″ | Very Good | Low to High |

| Shell Mold Casting | Medium | Medium | ±0.030″ | Good | Medium |

| Greensand Casting | Low | Medium | ±0.030″ | Fair | Low to Medium |

| Airset Casting | Low | High | ±0.063″ | Fair | Low |

Investment casting offers tighter tolerances and smoother finishes than other casting methods, particularly for complex, low-volume parts. While it may carry higher labor costs, its precision and repeatability often reduce or eliminate the need for secondary operations.

From Prototype to Full Production

Investment casting is also an excellent solution for prototyping, due to relatively low tooling costs and flexibility in the design phase. We support:

- Low-volume pilot runs

- Rapid design iteration and testing

To see a real-life example, view our Hydrant Guard Case Study.

Why Partner with Eagle Precision for Investment Castings?

Our value lies in:

- Engineering support from day one

- Precision across small to large production runs

- In-house design for manufacturability (DFM) guidance

- Trusted supplier network for heat treatment, coatings, machining, and more

- ISO 9001:2015 and PED certifications

We’re more than a casting shop. Eagle Precision is your long-term manufacturing partner who is committed to your success.

Contact us to request a quote for your investment casting project.